Internal Workshop

- Machining and turning on carbon and metallic parts

- Manufacturing of accessories

- Bonding of components

- Manufacturing of accessories

- Bonding of components

Machine List

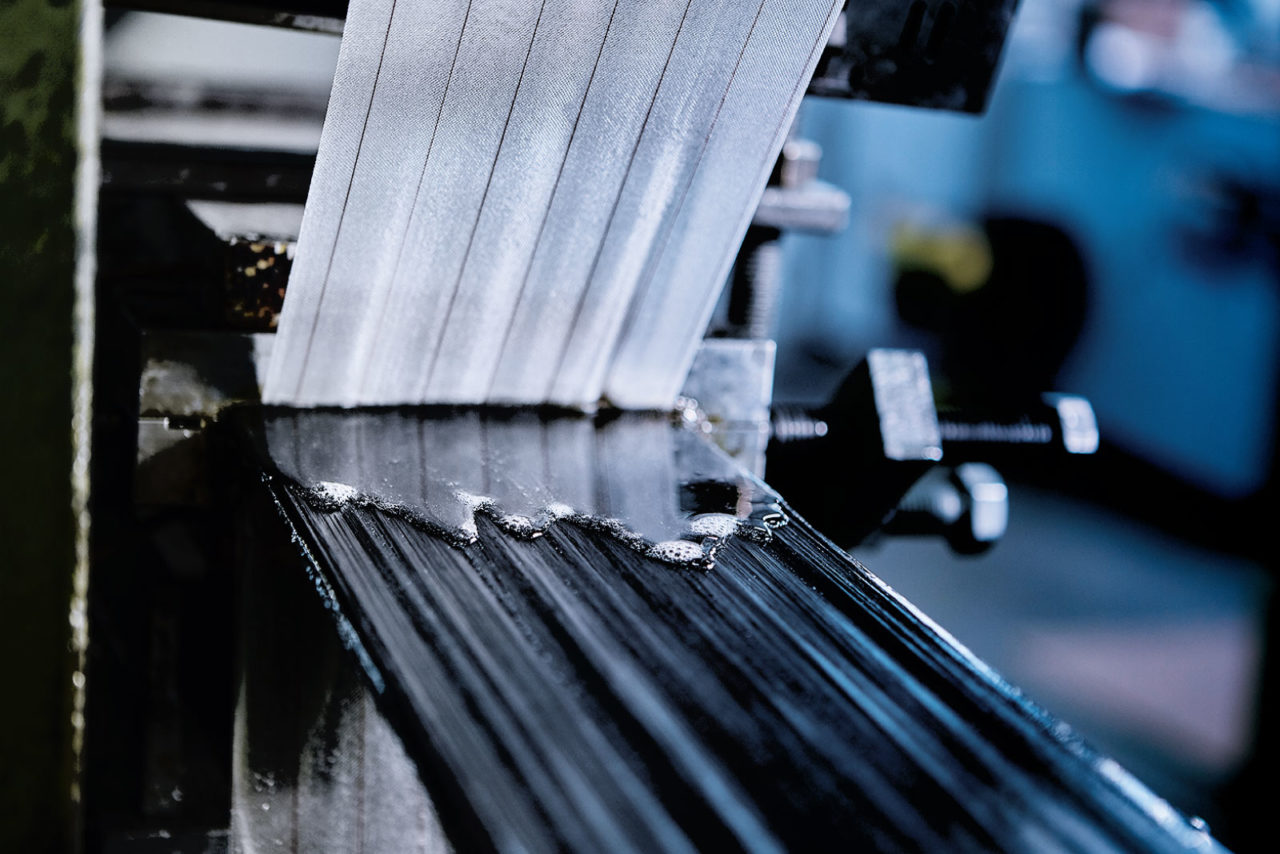

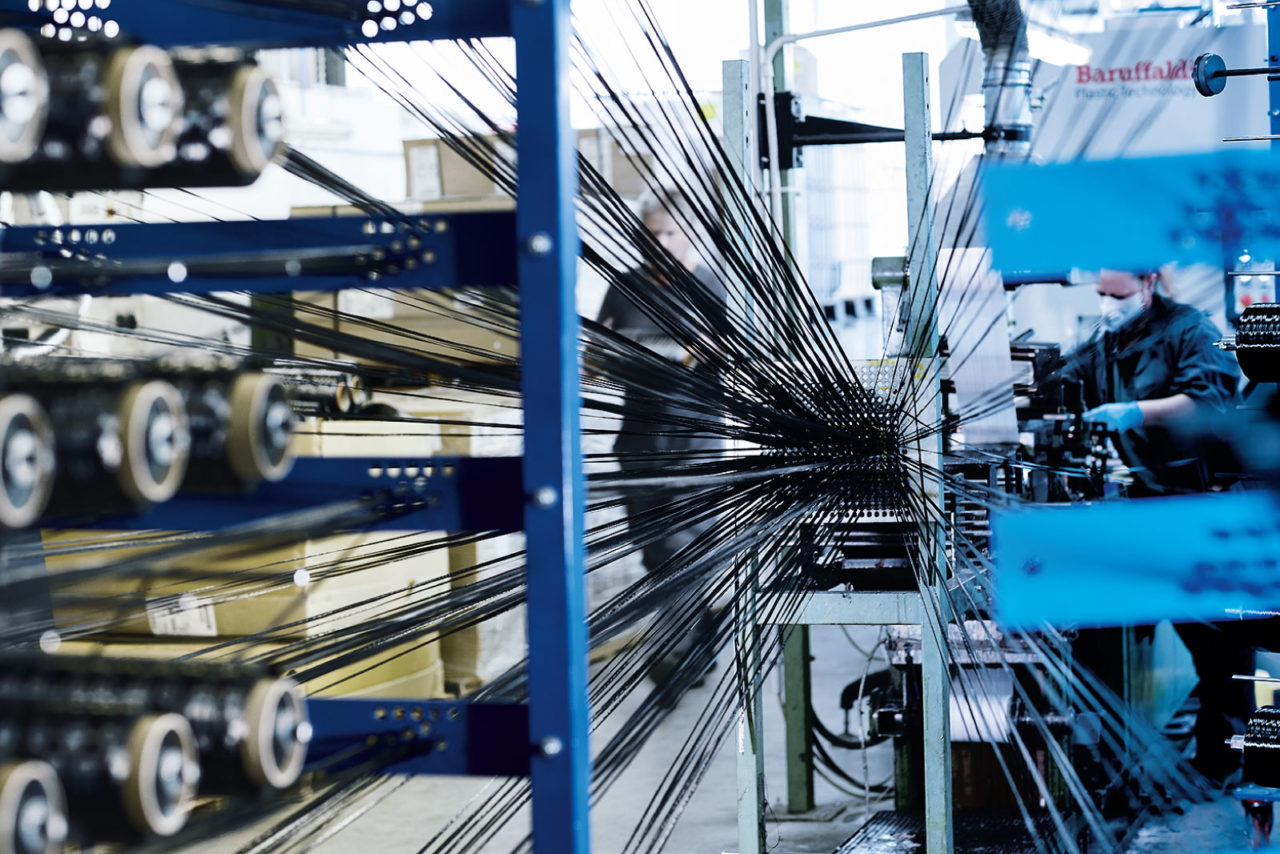

- Nr. 6 pultrusion lines, unidirectional

- Nr. 1 line for pullwinding, multidirectional

- Nr. 2 CNC machining centers

- Nr. 1 line for pullwinding, multidirectional

- Nr. 2 CNC machining centers

Engineering Department

- Design of components with 3D software

- Prototyping

- Prototyping

Additional operations:

CARBONVENETA is equipped to run additional operations to carbon pultruded profiles, according to customer drawings, in order to supply an immediately applicable semi-finished or eventually a finished product. These operations are:

-

Drilling

-

Milling

-

Carbon-carbon or Carbon-metal gluing

-

Gumming

-

Pad printing

-

Assembly

Additional operations:

CARBONVENETA is equipped to run additional operations to carbon pultruded profiles, according to customer drawings, in order to supply an immediately applicable semi-finished or eventually a finished product. These operations are:

-

Drilling

-

Milling

-

Carbon-carbon or Carbon-metal gluing

-

Gumming

-

Pad printing

-

Assembly

Internal workshop

- Machining and turning on carbon and metallic parts

- Manufacturing of accessories

- Bonding of components

- Manufacturing of accessories

- Bonding of components

Machine List

- Nr. 6 pultrusion lines, unidirectional

- Nr. 1 line for pullwinding, multidirectional

- Nr. 2 CNC machining centers

- Nr. 1 line for pullwinding, multidirectional

- Nr. 2 CNC machining centers

Engineering Department

- Design of components with 3D software

- Prototyping

- Prototyping

Let's get in touch

How can we help your business?

Carbonveneta cooperates with competence and synergy with its customers, for the best use the material properties of carbon fiber.

Contact us or request a quote