STRUCTURAL REINFORCEMENT

with carbon fiber

Carbonveneta develops and manufactures carbon fiber pultruded composites, designed for structural consolidation and restoration, to offer architects, engineers, and contractors reliable and certified solutions.

Carbon fiber: the design solution for structural consolidation

Whenever existing buildings and infrastructures are stressed by increasing loads or exposed to material degradation, consolidation works are required to restore their load-bearing capacity and ensure structural safety.

Carbonveneta offers cutting-edge solutions for structural restoration, in which technological innovation is combined with certified expertise.

Composite materials are now popularly used in all structural reinforcement and seismic retrofitting projects involving masonry, brick, stone or reinforced concrete buildings.

STRUCTURAL CONSOLIDATIONMajor benefits

of carbon fiber used in structural consolidation and restoration

Nowadays, carbon fiber is one of the most advanced materials for structural reinforcement thanks to its stunning lightweight-strength ratio. Its superior mechanical properties combined with durability and easy installation make carbon the ideal choice for all applications where the load-bearing capacity needs to be enhanced, without significantly increasing the loads on the existing structures.

- High mechanical strength and rigidity

- Lightweight

- Easy to install and small footprint

- Resistant to corrosion and the elements

- Radio transparency and insulating properties

- Excellent thermal insulation and durability

STRUCTURAL CONSOLIDATIONMajor benefits

of carbon fiber used in structural consolidation

Nowadays, carbon fiber is one of the most advanced materials for structural reinforcement thanks to its stunning lightweight-strength ratio. Its superior mechanical properties combined with durability and easy installation make carbon the ideal choice for all applications where the load-bearing capacity needs to be enhanced, without significantly increasing the loads on the existing structures.

- High mechanical strength and rigidity

- Lightweight

- Easy to install and small footprint

- Resistant to corrosion and the elements

- Radio transparency and insulating properties

- Excellent thermal insulation and durability

MAIN APPLICATIONSWhen should carbon fiber be used?

Carbon fiber can be used in a variety of contexts, making targeted and safe interventions possible.

Structural reinforcement inSeismic areas

Structural reinforcement inSeismic areas

- Securing of buildings affected by seismic events

- Retrofitting of buildings and structures to make them compliant with anti-seismic regulations, without invasive works

Rehabilitation and consolidation ofOld or damaged buildings

Rehabilitation and consolidation ofOld or damaged buildings

- Interventions on historical, industrial or residential buildings suffering from subsidence or structural damage, without jeopardising their appearance

- Structural reinforcement after a fire

Structural reinforcement forBuilding expansion or change of intended use

Structural reinforcement forbuilding expansion or change of intended use

- To increase the beam and floor load-bearing capacity in expansion projects or for a new intended use, with time-saving and poorly invasive works

- • Quick applications thanks to lightweight and high resistance materials.

Improvement ofStructural performances

Improvement ofStructural performances

- To protect the existing structures by way of preventing their cracking and degradation, increasing their service life, and minimising the need for future interventions

- To enhance fatigue strength and resistance to cyclic stress

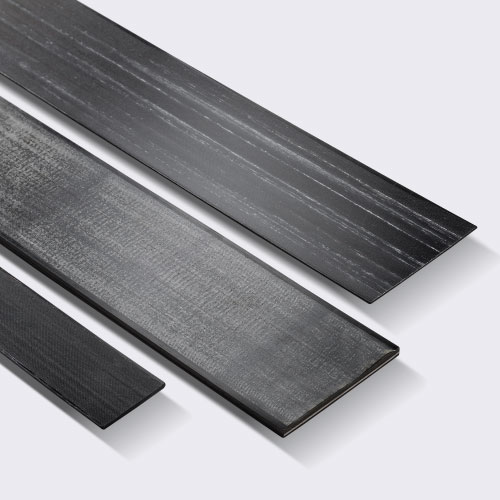

Discover our products forStructural Reinforcement

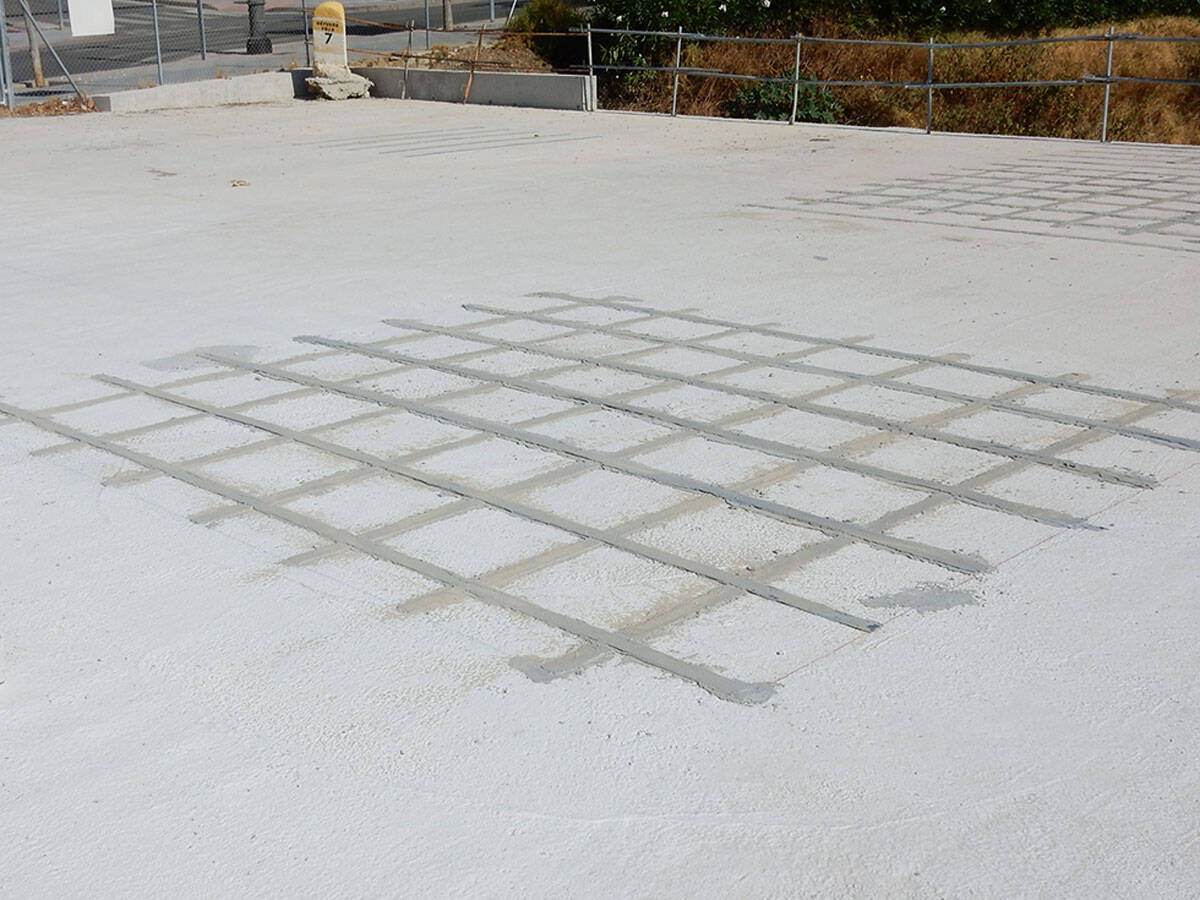

Application examples:

• Concrete Reinforcement

• Anti-seismic structures

• Excellent in general renovation

• Horizontal or oblique reinforcement for beams, slabs, roofs, domes

• Cantilever reinforcement for terraces or similar

• Vertical reinforcement for plinths and columns supporting walls

Application examples:

• Concrete Reinforcement

• Anti-seismic structures

• Excellent in general renovation

• Horizontal or oblique reinforcement for beams, slabs, roofs, domes

• Cantilever reinforcement for terraces or similar

• Vertical reinforcement for plinths and columns supporting walls

FAQ - frequent ask questions

Carbon is a material that combines innovation, performances and reliability. If compared to other conventional materials, its lightweight and superior mechanical strength make it the ideal choice for consolidation works and improvement of seismic performance. It is the most suitable solution when you wish to consolidate a structure in an efficient, quick and poorly invasive manner.

Carbon is an advanced composite material combining lightweight, strength and durability.

Carbon fibers are processed by pultrusion into products starting from pure fibers of carbon procured from leading producers. Carbonveneta uses high-quality carbon fiber types, such as 3K, 6K, 12K, 18K, and 24K, soaked in epoxy resin to manufacture products with high mechanical properties.

Distinctive technical properties of carbon:

- Extremely high tensile and flexural strength: carbon offers superior strength if compared to other conventional materials. Module of elasticity range: E = 140 – 150 – 170 – 200 – 250 – 280 GPa. Tensile strength range: R = > 1800 or > 2300 MPa.

- Unparalleled rigidity-lightweight ratio: helps build robust structures, without significant weight increases.

- Resistance to chemical corrosion and salty environments: carbon has an almost unlimited resistance in salty environments and to aggressive chemicals.

- Excellent adhesion: for easier glueing to and incorporation in other materials.

- Dimensional stability: keeps its properties over time, including in variable conditions.

- Vibration dampening: mitigates the risk of structural damage resulting from dynamic vibrations.

- Radio transparency: no interference with electromagnetic signals, which is helpful in specific applications.

- High electric conductivity: suitable for applications requiring conductive properties.

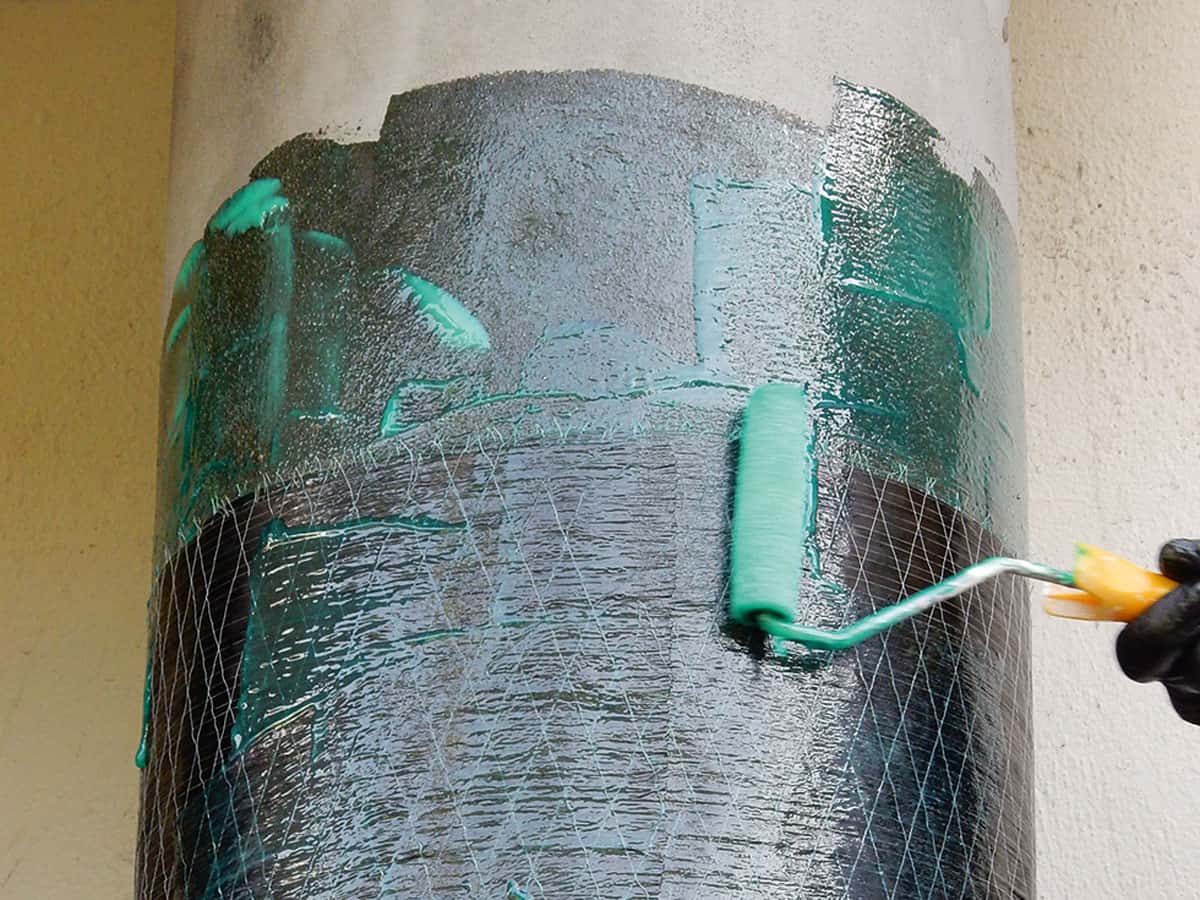

Different structural restoration solutions exist that use systems made of fiber-reinforced composite materials to enhance the strength, safety and durability of existing buildings. The most popular techniques include FRP, FRCM and CRM composite materials.

What are FRP composites?

FRP composites (Fiber Reinforced Polymer) are composite materials made of fibers (carbon, glass or aramid) soaked in a polymeric matrix (typically epoxy resins).

The fibers provide strength and rigidity, and the polymeric matrix distributes the loads and protects the fibers.

Major applications include:

- Reinforcement of beams, pillars and walls made of reinforced concrete or masonry;

- Enhanced load-bearing capacity and ductility;

- Better seismic performance of structures.

What are FRCM composites?

FRCM composites (Fiber Reinforced Cementitious Matrix) are advanced materials consisting of high-resistance fiber meshes incorporated in a cementitious matrix. The cementitious matrix sticks to the surface of the structure, and the fibers reinforce it mechanically.

These materials are an effective solution to provide structural reinforcement of existing buildings.

Major applications include:

- Consolidation of historical walls or buildings made of stone;

- Structural reinforcement of elements exposed to high loads;

- Improvement of seismic performance of structures under conservative restraints.

What are CRM composites?

CRM composites (Composite Reinforced Mortar) are reinforcement systems that use fibers in preformed meshes embedded in lime- or cement-based mortars. They are mostly fit for the consolidation of historical walls thanks to their compatibility with traditional materials and their high transpiration properties.

The quality of the products manufactured by Carbonveneta is confirmed by the Certification of Technical Suitability and the Certification of Technical Assessment that certify product compliance with the regulations in force and material reliability for structural consolidation projects. CIT and CVT certifications are Italian technical validations for Fiber-Reinforced Polymer (FRP) systems used in structural reinforcement.

Almost all our customers have the Certification of Technical Suitability/Technical Assessment for our products, which is also supported by our certifications, as this is now an ESSENTIAL requirement for public projects and more and more frequently for private applications as well.

Thanks to our massive and continual investments in research and development, and in our new production systems, we at CARBONVENETA have worked out some reinforcement techniques that make our pultruded composite material particularly resistant along directions other than the main axis. We can therefore manufacture MAT reinforced pultruded composites or products by pullwinding where traditional anisotropy is modified, which offers strength along directions other than horizontal.

The products by Carbonveneta offer sustainable and performing solutions which include:

- reduced weight of structures, if compared with traditional reinforcements;

- durable materials, which reduces future maintenance and interventions;

- focus on cutting-edge technology and respect for the environment.

STRUCTURAL REINFORCEMENT PROJECTSOur projects

Carbon fiber profilesFabrication process

in order to supply an immediately applicable semi-finished or eventually a finished product.

These operations are:

- Drilling: our carbon fiber profiles can be drilled to achieve the requested holes quantity and diameter, either using manual tools or with a CNC machine, according to customer’s drawings.

- Milling: our carbon fiber profiles can be machined or drilled with CNC machines, according to customer’s drawings.

- Carbon-carbon or Carbon-metal gluing: in order to build assemblies we can manufacture metal joints that be co – engineered with the customer.

- Gumming: we can apply gum coating to carbon fiber paddles, in different colours, lengths and thicknesses. Our paddles can be used in a wide range of machines, for instance pallettisers, robots, lifters, etc.

- Pad printing: upon request we can supply our carbon fiber parts including pad printing.

- Assembly: upon request we are able to co-design and manufacture assemblies, in order to satisfy a wide range of customer demands.

Internal Workshop

- Manufacturing of accessories

- Bonding of components

Machine List

- Nr. 1 line for pullwinding, multidirectional

- Nr. 2 CNC machining centers

Engineering Department

- Prototyping

Get in TouchGet a free quote

Flexible and fast

delivery services

Carbonveneta manufacturing is entirely carried out within its own facilities