TecnologyCarbon Fiber performance

Proprietà

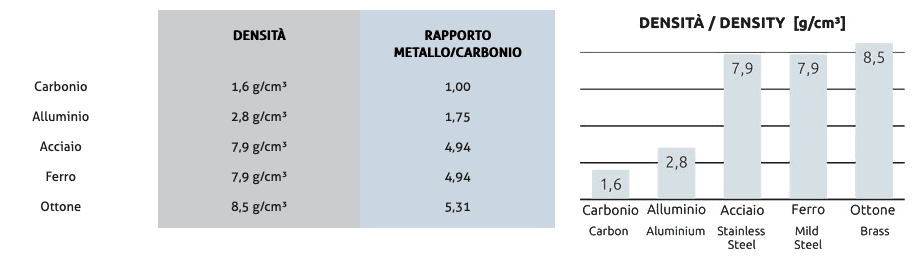

Sono dunque da sottolineare tutte le importanti proprietà del carbonio al fine di dare spazio a nuove applicazioni sfruttando a pieno tutte le sue potenzialità.

Si rimanda alle “Schede tecniche” di ciascun prodotto per informazioni più approfondite.

The carbon fiber applications are constantly increasing, as a standard material in domestic and industrial applications, structural, aesthetic, performing. Consequently, all the important properties of carbon fiber must be highlighted.

Please refer to the "Technical Data Sheet" of each product for more detailed information.

The carbon fiber applications are constantly increasing, as a standard material in domestic and industrial applications, structural, aesthetic, performing. Consequently, all the important properties of carbon fiber must be highlighted.

Please refer to the "Technical Data Sheet" of each product for more detailed information.

Sono dunque da sottolineare tutte le importanti proprietà del carbonio al fine di dare spazio a nuove applicazioni sfruttando a pieno tutte le sue potenzialità.

Si rimanda alle “Schede tecniche” di ciascun prodotto per informazioni più approfondite.

Sono dunque da sottolineare tutte le importanti proprietà del carbonio al fine di dare spazio a nuove applicazioni sfruttando a pieno tutte le sue potenzialità.

Si rimanda alle “Schede tecniche” di ciascun prodotto per informazioni più approfondite.

Technical data

Carbon fiber properties

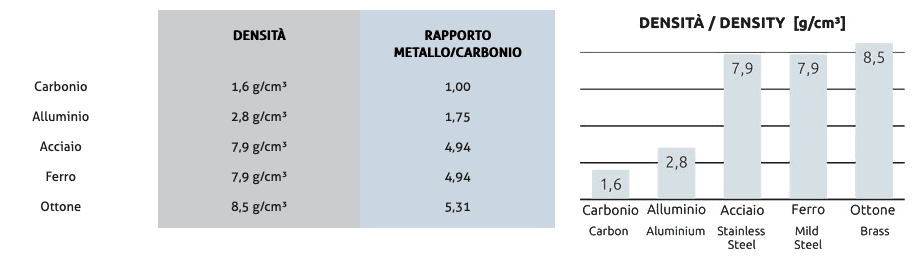

Fibers

The carbon fiber profiles are produced with pultrusion technology starting from pure carbon fibers of primary manufacturers mixed with an epoxy resin.

Types of fibers:

3K – 6K – 12K – 18K – 24K (K = thousands of fibers)

Very high tensile strength

- Elastic modulus range

E = 140 – 150 – 170 – 200 – 250 – 280 GPa - Tensile strenght range

R = > 1.800 o > 2.300 MPa

In the picture: element of a carbon aluminum crane

Resistance to chemical and saline corrosion

Carbon has almost unlimited resistance to saline environments and aggressive chemicals.

- Bridges, viaducts

- Concrete structures facing the sea

- Docks

- Nautical

- Chemistry

- Welding machines

- Immersion in sea water

Rubbering

With the carbon rubbering process, very high performance surfaces (palettes) are obtained with very high wear resistance and perfect adhesion carbon – rubber foil.

The application of gripping pallets is excellent on the following applications :

- Robots

- Palletizers

- Basketing machines

- Anthropomorphic or Cartesian gripping heads.

- Rollers

Radiotransparency

Radiotransparency offers wide application possibilities in the orthopaedic and telecommunications field. In fact, the carbon elements are transparent to X-rays and therefore allow the construction of objects that must not be removed during the radiography. Similarly protections of antennas, radars, radio transmitters generally made of carbon allow clean transmissions without any interference or attenuation.

- Fixators

- Orthopaedic devices

- Stretchers

- X-ray beds

- Radar and antenna protection

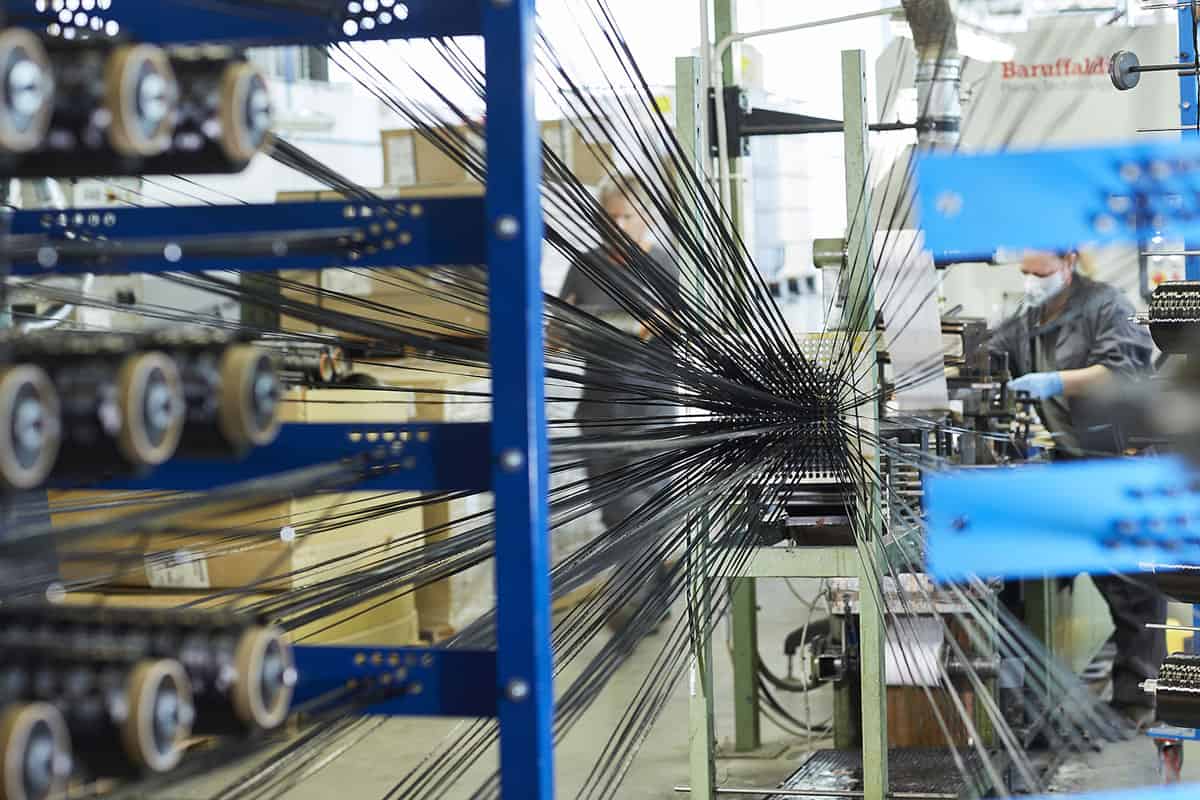

Good electrical conductivity

Carbon fiber profiles and tubes are commonly used in the paper, fabric and film industry as they are antistatic.

In the picture: carbon elements for the antistatic paper industry

Adhesion - Bonding

▪ CARBON - METAL

▪ CARBONIO - WOOD

▪ CARBONIO - CONCRETE

▪ CARBONIO - MASONRY

dedicated adhesives and resins are available for each type of joint..

Normally two components adhesives are available on several brands for the most wide applications (internal-external-hot-cold-elastic-rigid-wet- dry).