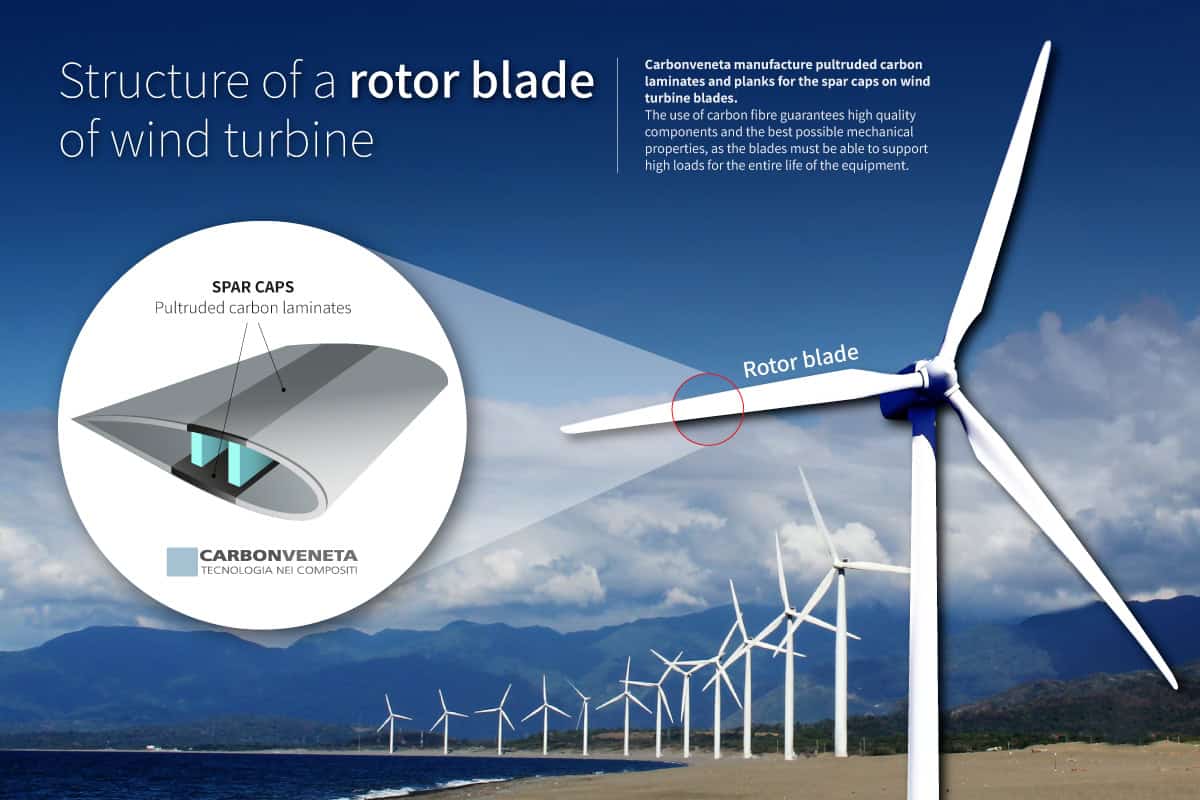

Pultruded carbon laminates and planks are used as a reinforcing element inside the rotor blades of wind turbines.

The use of carbon fibre, which guarantees high quality components and the best possible mechanical properties, as the blades must be able to support high loads for the entire life of the equipment.

- DESCRIPTION

- TECHNICAL FEATURES

The pultrusion process of our laminates allows stability and constant quality assurance during the production of large quantities.

- Very high tensile strength

- Elastic modulus between 140 GPa and 280 GPa

- Exceptional stiffness-to-weight ratio

- Dimensional stability and arrangement of the composite.

- Chemical corrosion resistance

- Resistance to saline environments

- Vibration absorption

- High electrical conductivity

- Packaging in rolls starting from 50 meters

Get in Touch!Get a free quote

We are happy to help you with your enquiry.

Open profiles

Open profiles

Mettiamoci in contatto

Come possiamo aiutare il tuo business?

Carbonveneta collabora con competenza e sinergia con i propri clienti, per sfruttare al meglio le proprietà dei materiali in fibra di carbonio, grazie ai quali è possibile esprimere soluzioni progettuali innovative e di grande pregio.

Contattaci o richiedi un preventivo