Spar Caps

A significant step towards innovation in the wind turbine industry.

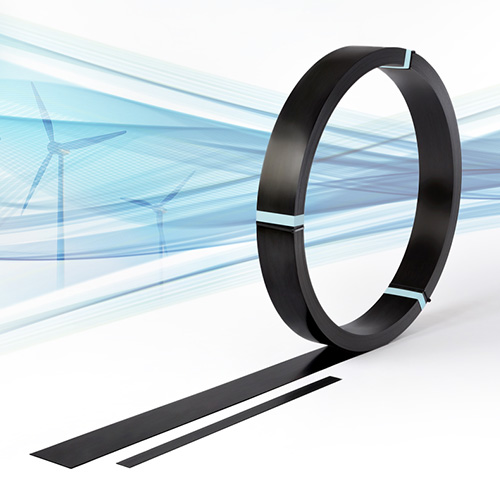

The pultruded carbon planks, used as a reinforcing element inside the rotor blades of wind turbines, represent a significant innovation in terms of quality, duration and efficiency.

Until a few years ago, with turbines having blades 10-15 meters long, fiberglass was commonly used while today, with off-shore turbine blades that can even reach 130 meters in length, it is essential to use carbon fiber which guarantees high quality components and the best possible properties, as the blades must be able to support high loads for the entire life of the equipment.

The manufacturing of these profiles is entirely carried out inside our plant in Italy and is the result of years of research and development in the renewable energy sector; our technicians have worked closely with engineers and industry experts to develop a solution that offers superior performance and a high level of reliability.

Carbon fibre profiles, well known for their lightness and stiffness, represent the ideal material for building the spar caps that reinforce large wind turbine blades, helping to improve the stability and life of the blades themselves. Thanks to these new components, wind turbines can face extreme conditions and support heavy loads, ensuring optimal plant efficiency.

We are proud to be able to offer a Made in Italy product that guarantees uncompromising quality, durability and reliability. With our carbon fiber components, turbine blades will be able to successfully meet the future challenges of renewable energy.

The carbon fiber planks for Spar Caps have already been used by several wind turbine manufacturers, who have recognized their benefits. The renewable energy industry is pushing more and more towards solutions that maximize efficiency and sustainability and pultruded carbon planks represent a fundamental step forward in this direction.