We design and manufacture advanced structural systems by replacing traditional heavy materials with high-modulus carbon fiber profile and ergal connections. The result is an ultra-lightweight architecture that drastically minimizes moments of inertia and unlocks your machinery’s full potential: reduced mass translates directly into superior dynamic response and minimized energy consumption.

- DESCRIPTION

- TECHNICAL FEATURES

- SERVICES

The perfect combination that allows modulating the two most important factors involving mechanical parts or assemblies, according to design needs:

• Physical performance intended as rigidity and resistance

• Weight, or rather lightness.

- Lightness

- Speed

- Zero Inertia

- Energy saving

- Resistance to chemical environments

- Memory of shapes

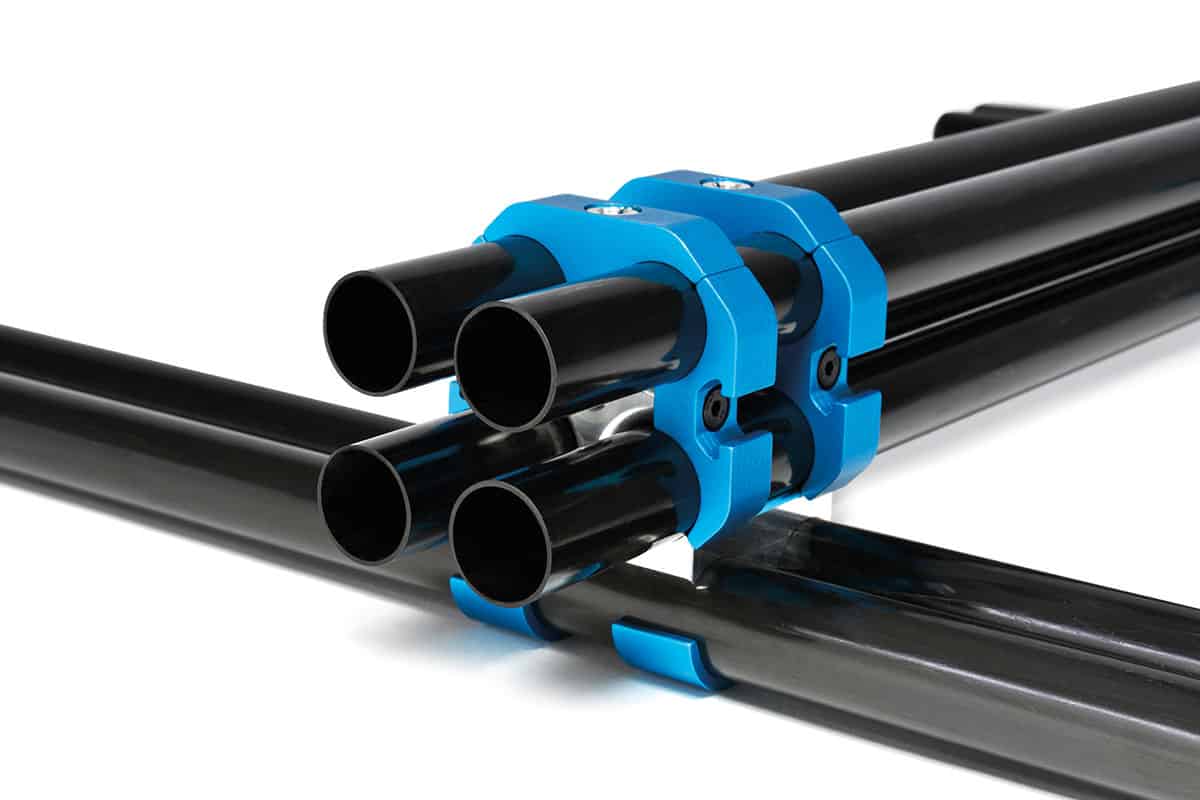

- Versatility

- Extensibility

Custom design & manufacturing: we analyze your specific operational requirements to engineer and produce bespoke modular systems, precision-optimized for your unique industrial application.

Specialized technical consulting: our team provides dedicated engineering support throughout every project phase—from initial feasibility studies to comprehensive after-sales assistance—ensuring seamless integration of our systems into your workflow.

Applications for the industry

INDUSTRIAL AUTOMATION

APPLICATION EXAMPLE

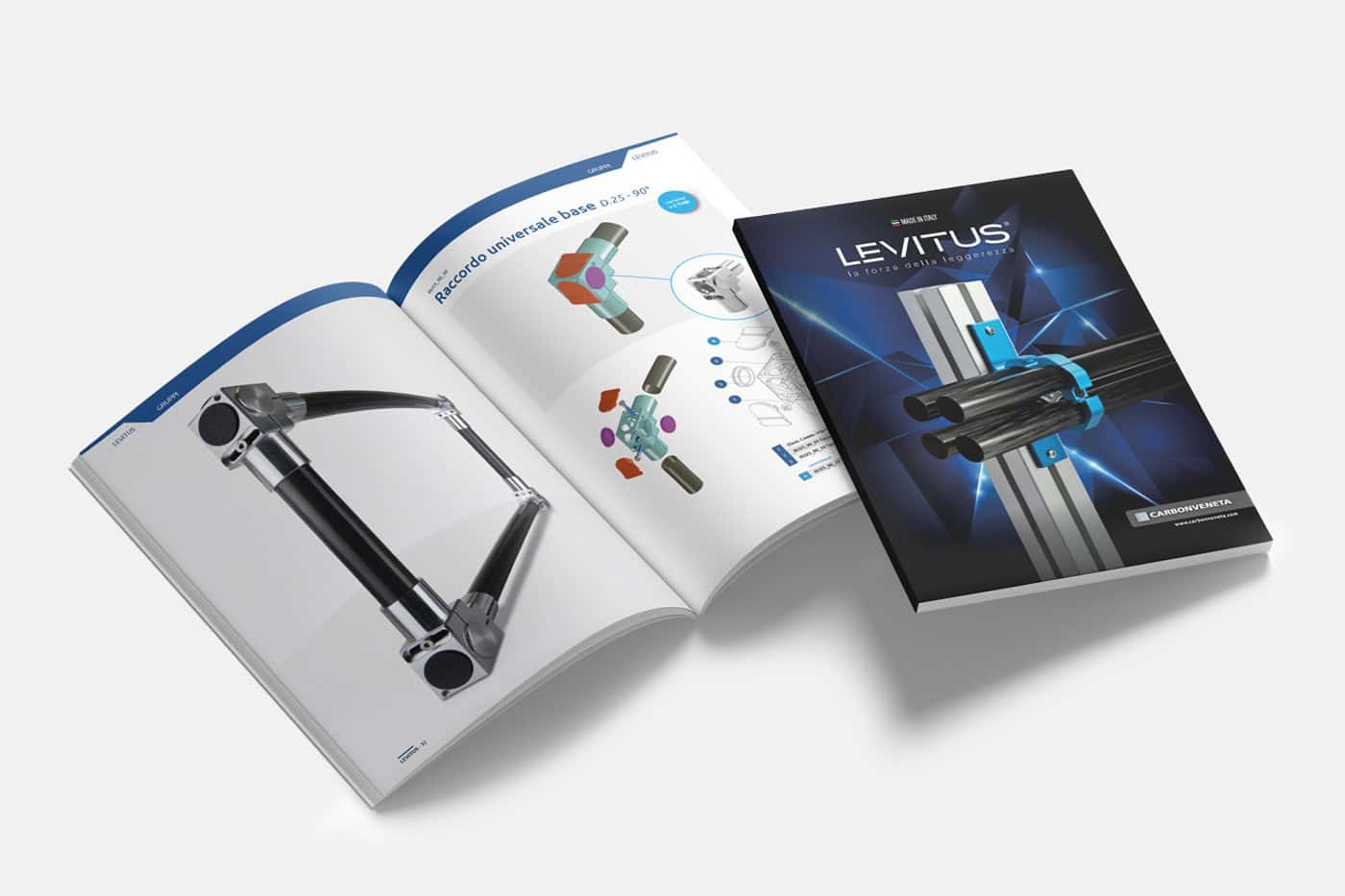

Request the LEVITUS® Catalog

For additional inquiries, please contact our Sales Department.

Request the LEVITUS® Catalog

For additional inquiries, please contact our Sales Department.

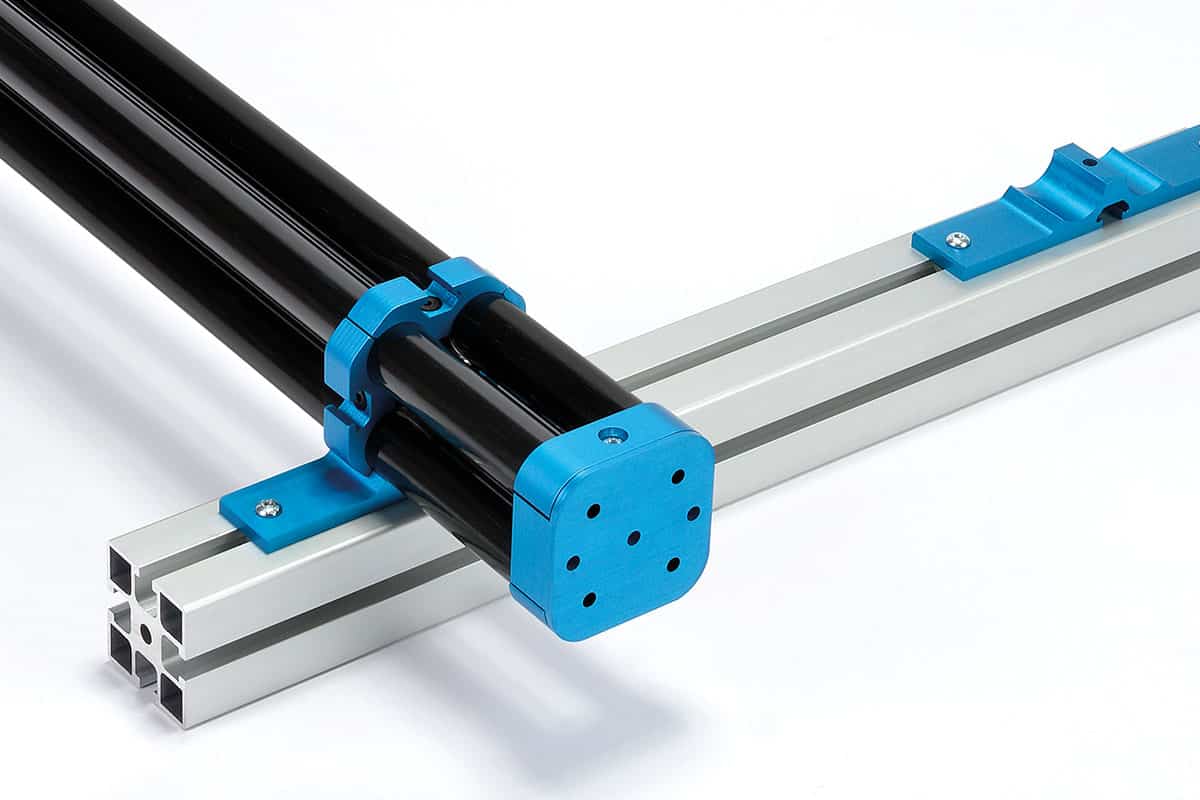

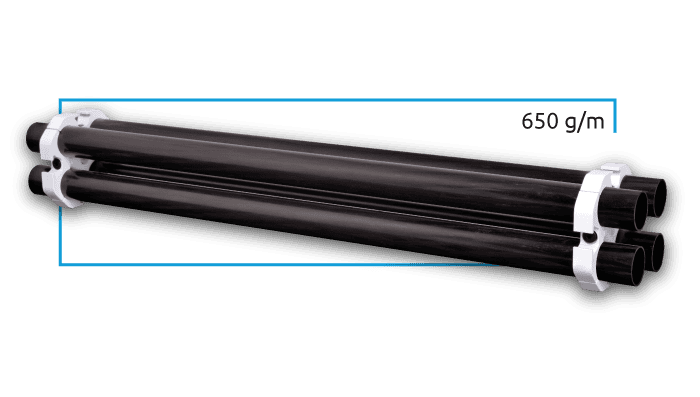

Basic system

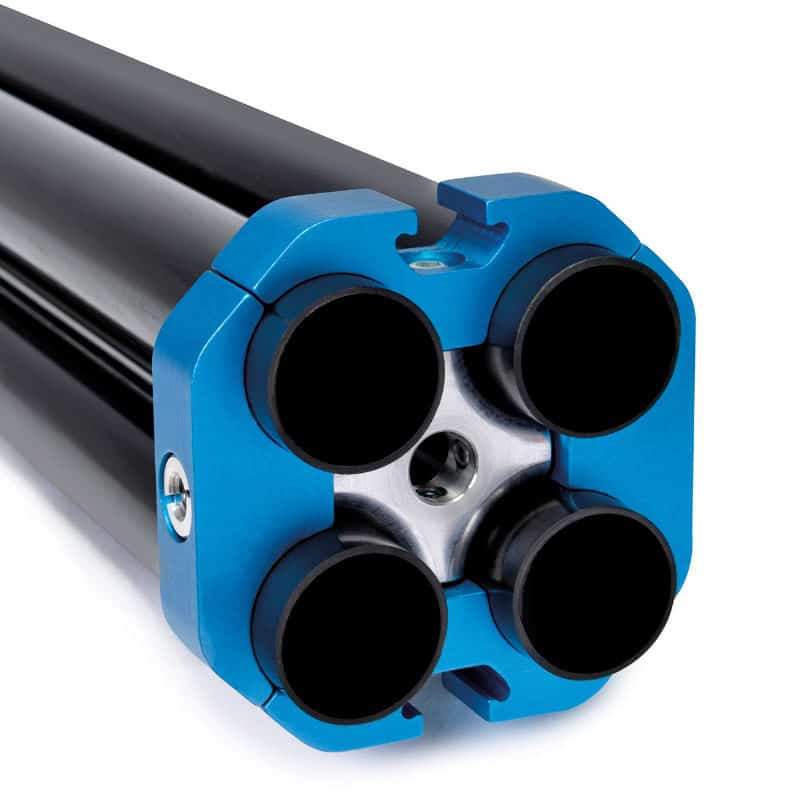

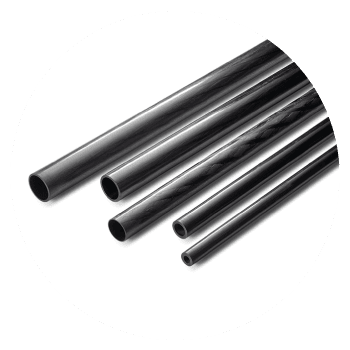

Carbon Fiber Tubes

Carbon is the new frontier of materials, a substance that is revolutionizing numerous industries thanks to its extraordinary properties. With its incredible lightness and strength, it ensures exceptional performance in contexts that require high performance without adding weight to the structure. Carbon fiber, in particular, offers a unique combination of rigidity, durability, and flexibility, making it ideal for applications ranging from automotive to aerospace, and extending to the energy, construction, and automation industries.

• Elastic Modulus: E = 150 GPa / 250 GPa

• Tensile Strength: R = 1800 MPa / 2300 MPa

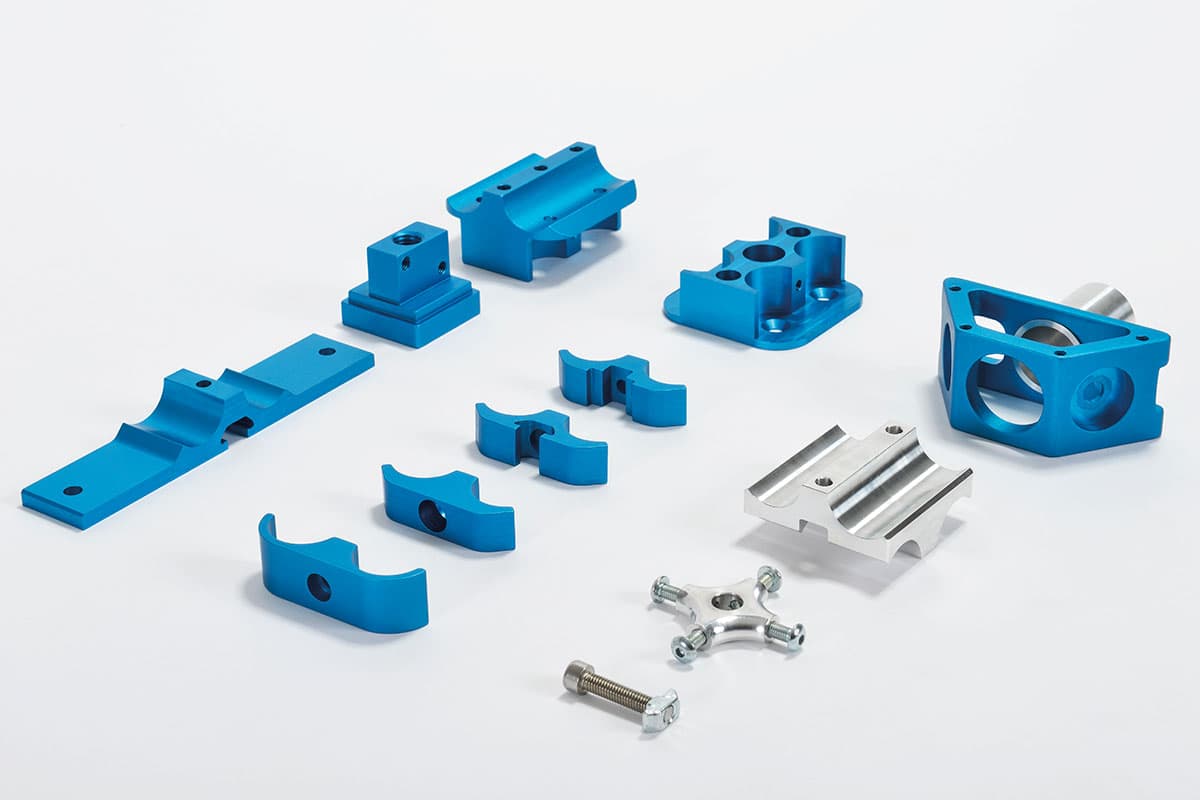

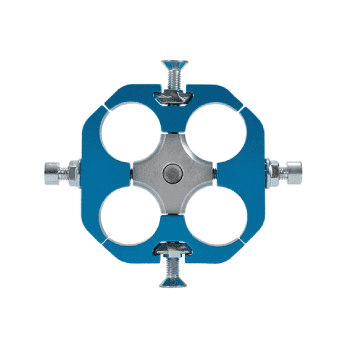

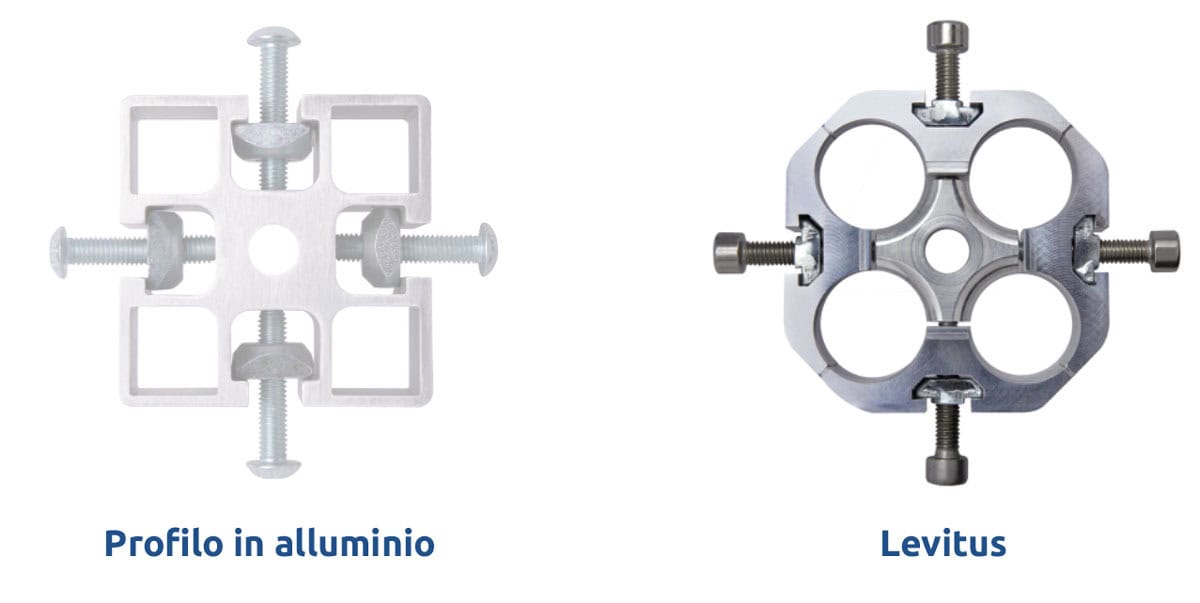

Ergal Connections

Ergal, technically known as aluminum alloy 7075, is renowned for its exceptional mechanical properties and versatility. Made primarily of aluminum with additions of zinc, magnesium, and copper, it offers a combination of lightness and strength, making it ideal for advanced applications.

• High mechanical strength: with a tensile strength of up to 572 MPa, Ergal is one of the strongest aluminum alloys available, comparable to some steels.

• Lightness: the density of Ergal is around 2.81 g/cm³, significantly lower than that of steel.

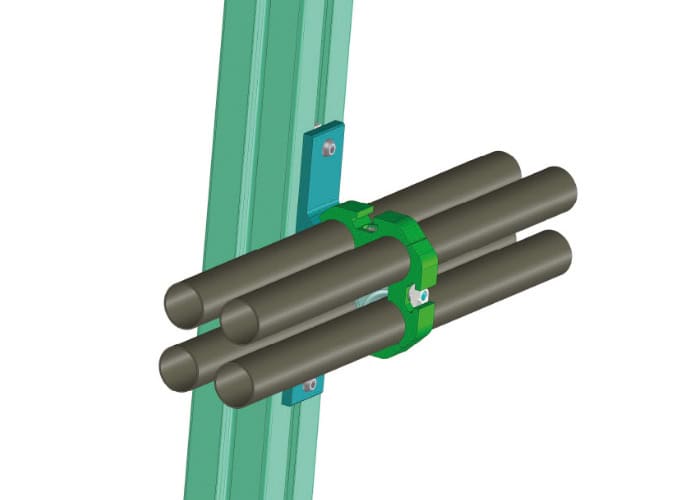

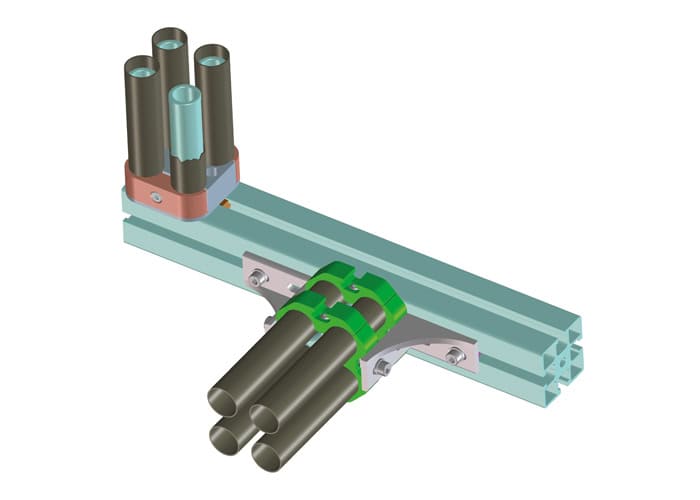

Intuitive fastening

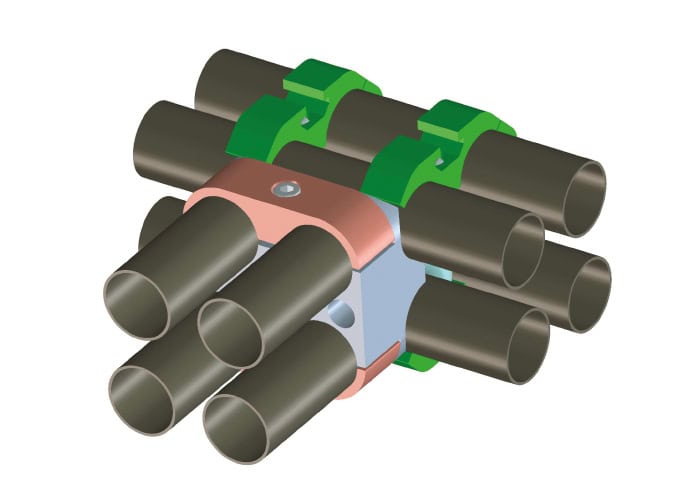

Examples of Combinations

Get in Touch!Get a free quote